We are sure you can agree that avoiding accidents and injury in the workplace is a priority. Especially as accidents impact people, resources, equipment, and our environment. C3 continues to focus on improving the safety of our employees, and one of the risks we wanted to mitigate was collisions with heavy equipment. Heavy pivot loaders pose an alarming risk of incidents because they lack the necessary vision and peripheral equipment to help them avoid colliding with other vehicles, pedestrians, or objects.

To mitigate risk and improve the safety of our employees, we decided to work with the best in the field – SEEN Safety. This award-winning New Zealand-based company has rolled out this safety technology in over 20 countries worldwide.

IRIS 860 works together with your PPE.

This widely recognised safety technology transforms the retroreflective beads commonly found on High Viz PPE, vehicle decals and other fixed objects into an active safety system. IRIS 860, SEEN Safety’s flagship product, can detect and alert to the presence of reflective material within a set detection zone.

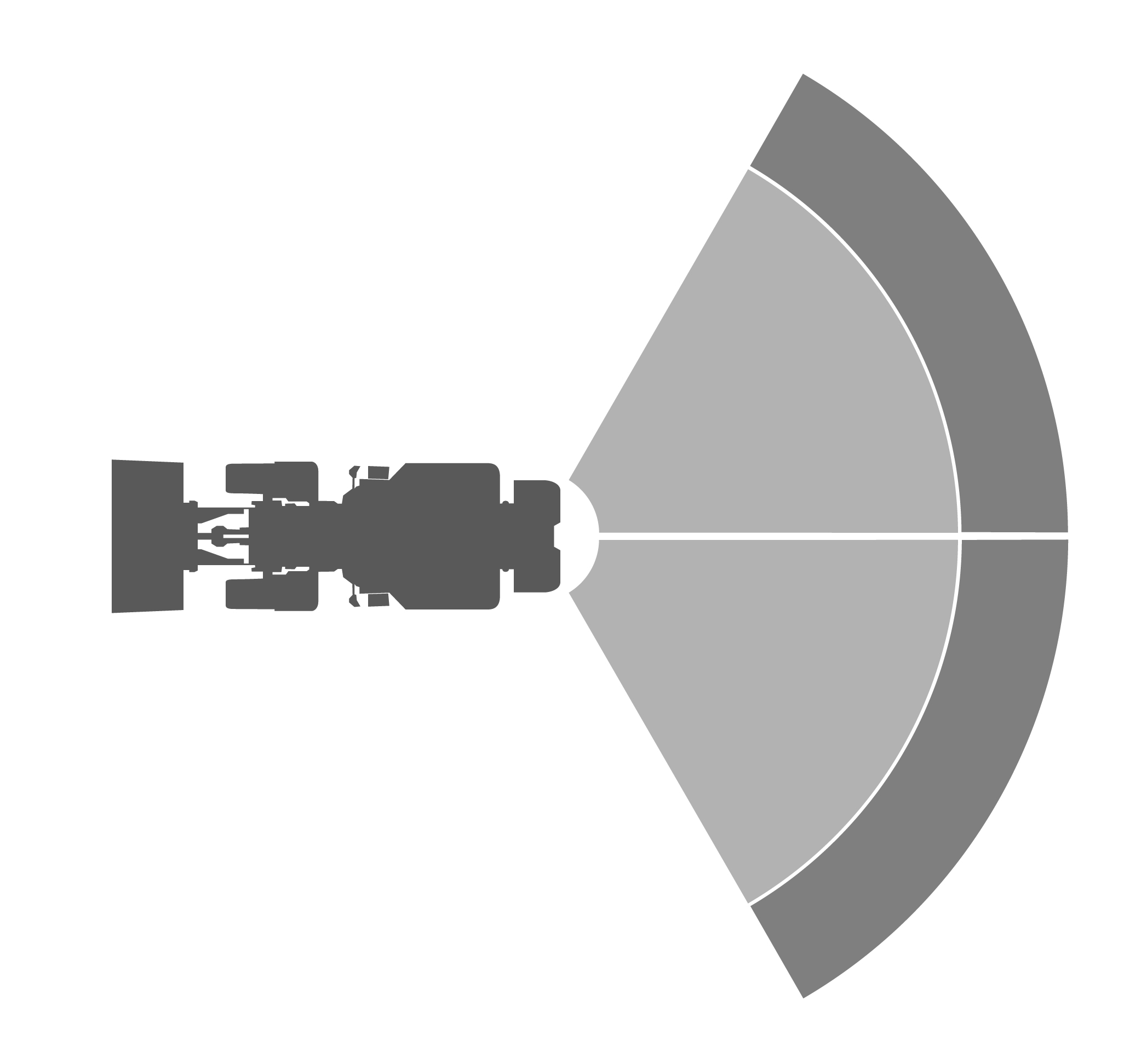

Sensors mounted on the loader’s log head provide front coverage, and those placed on the rear bonnet detect objects approaching from behind. When a vehicle or pedestrian with the appropriate reflective materials passes through the detection zone, an audible alarm sounds to alert both driver and the subject.

Each individual sensor provides a 60°x45° detection zone, but the multizone pairing extends to 110°. The range of the sensors is 8 meters, which can be reset if necessary, in order to reduce false alarms.

This environment requires the sensor to be robust and safe to function optimally and not interfere with other activities. Custom housing protects the sensor in the log heads; the units are shock and vibration resistant. IRIS 860 contains a Class 1 eye-safe infrared laser. As such, they do not require any additional laser beam control measures. The technology does not pose a risk of interference with RF equipment critical to operational safety.

We have fitted twenty-six per cent of our loader fleet with front and rear scanners and thirty-four per cent with rear only. The implementation of this safety technology is making high-risk workplace environments safer. However, it’s crucial to remember that adding new technologies cannot replace or lessen the importance of proper training and compliance with established practices—we must remain vigilant despite technological advances!